by Julie Angus

At Angus Rowboats, our passion for adventure naturally draws us to the mystique of the Northwest Passage – one of the world's most captivating and perilous waterways. Historically, this elusive passage promised a shorter shipping route, spurring early navigators to fervently chart and struggle through its icy intricacies.

The summer of 2023 saw three audacious teams, including one using our very own RowCruiser boats, aiming to be the first to traverse NW Passage solely by human power within a single season. As the season concludes, we've chronicled these attempts, and catalogued past human-powered endeavors to navigate the Northwest Passage.

Read More

by Colin Angus

A good boat is a versatile boat. Our wheelbarrow boat is good in and out of the water. It can be used to haul bags of concrete around the construction site, is a vehicle to go crabbing with the kids, or it can be transformed into an elegant bookcase.

Read More

by Julie Angus

Our boat kits are shipped from the PNW, and delivered to customers in the US and Canada. Due to prohibitive shipping costs, we do not ship our boat kits outside of North America. Building from plans is one alternative, however, some would prefer to build from a kit.

Read More

by Colin Angus

In 1987, a pilot by the name of Robert Plath invented a new kind of suitcase - the Rollaboard. It had two wheels and a rigid stowaway handle. While a pretty basic concept, it was revolutionary compared to what already existed (suitcases four wheels and leash that always fell over), and now almost every suitcase is designed in his style.

We feel that the Wheelbarrow Dinghy is to the world of boats that the Rollaboard is to suitcases...

Read More

by Colin Angus

6 Comments

Some boats are shaped so that all water that comes aboard is removed with gravity. This is how a typical cruising sailboat works. The cockpit is raised above the waterline, and a simple drainage system allows water to quickly flow away.,..

Read More

by Colin Angus

4 Comments

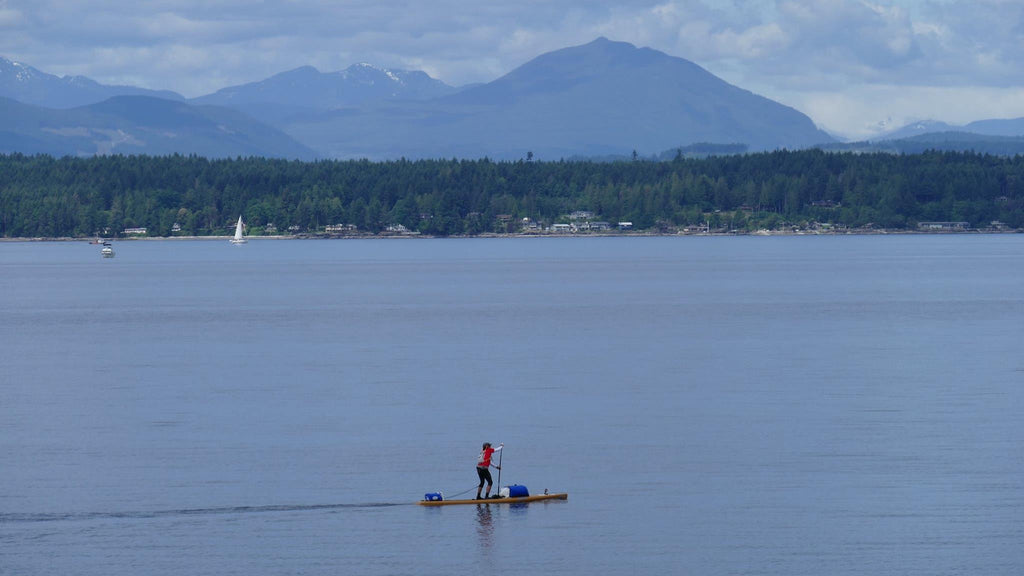

The first day of leg 1 for the 2022 Race to Alaska proved to be one of the most dangerous days in the history of the race. Four boats required rescues, three having capsized and another dismasted. The majority of the boats in the race didn’t even attempt to cross the treacherous Juan de Fuca Strait in these conditions. Boats that did successfully complete the crossing were the larger sailing boats. Gale force winds combined with extraordinarily powerful ebb flows created chaotic sea states with steep breaking waves up to 10’ in height. It was in this maelstrom that I found myself with an Expedition Rowboat...

Read More

by Angus Rowboats

1 Comment

One of the best ways to become better at something is to learn from someone who's already walked that road, or in our case built that boat. We wanted to share some stories of builders who've built our boats and have launched a new section called Featured Boatbuilder.

Read More

by Angus Rowboats

Kids 5 and younger can try the Bumblebee Sailboat at the Port Townsend Wooden Boat Festival on Sept 10-12. It's free and sign-up is at the pool. For those of you near Port Townsend, the Boat Festival is a great way to see a huge number of classic, innovative and beautiful wooden boats, as well as attend presentations and there's even hands-on activities for kids.

Read More

by Angus Rowboats

4 Comments

The geometry of fixed seat rowing is completely different from sliding seat rowing, but equally important for performance and comfort. There are many variables including length of oars, location of rowing seat relative to the boat, position of foot brace, height of oarlocks above seat, height of oars, height of seat above bilge, and the spread of the oarlocks. Additionally, there are factors to consider with the oars, such as spoon blade vs flat and weighted vs non weighted handles.

Read More

by Angus Rowboats

The last few days of R2AK have included some remarkable finishes. Team Ketch Me if U Can reached Port Townsend on June 19th, finishing 4th overall and completing the race in 7 d 15 h, making them the fastest 20 foot and under boat ever to finish. Plus they now hold the $10,000 buy back cheque, as they’re the first team to reach Ketchikan willing to sell their boat for 10K. Congratulations!

Read More

by Angus Rowboats

The weekend brought steady progress for many boats. Two more boats crossed the finish line yesterday, bringing the total in Ketchikan to 5. That leaves 23 boats still out there including all under 20 foot boats.

Read More

by Angus Rowboats

It was a nail biter of a day yesterday, with Team Broderna and Freeburd racing to the finish within shouting distance of each other. After 700 miles of charging along the tumultuous and rugged west coast, the boats were within 5 minutes of each other. The last stretch to Ketchikan was calm and it all came down to their pedal drives propelling their weighty multi-hulls to victory.

Read More